Why Manufacturing Needs Serious PIM

Manufacturers live in a world of exploding product data, thousands of SKUs, ever-changing specifications, regional variants, certifications, and channel-specific requirements. When this information is scattered across ERP fields, spreadsheets, PLM exports, and individual desktops, even simple updates become slow, error-prone projects. The result is inconsistent catalogs, delayed launches, and sales teams sending outdated datasheets to customers. In a market where buyers expect precise, comparable, and up-to-date technical information before they even speak to sales, messy product data is no longer just an operational headache; it is a direct threat to revenue and reputation.

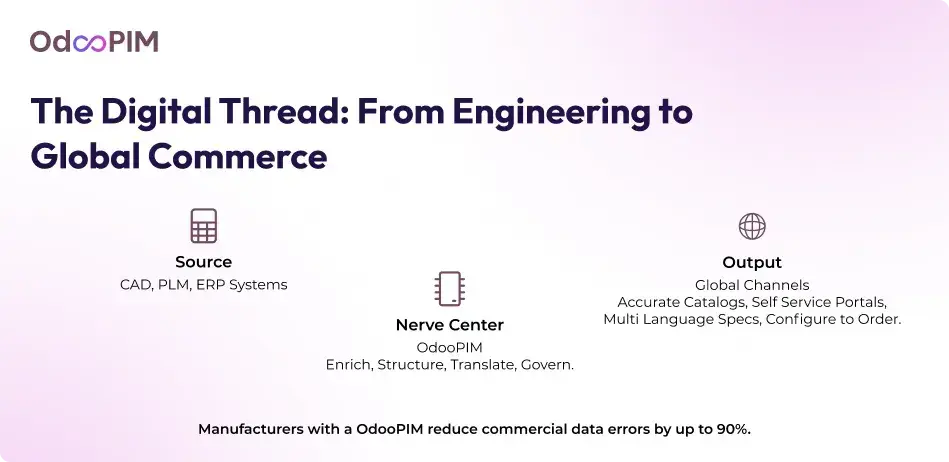

A Product Information Management (PIM) system turns that chaos into an advantage for manufacturing organizations. A PIM software becomes the single source of truth for every product and configuration, located between design, operations, marketing, and every outbound channel. It centralizes specifications, certifications, media, and localized content, applies validation and governance, and then syndicates clean, consistent data to websites, distributor portals, marketplaces, and partner networks in a controlled, automated way. With PIM software in place, manufacturers shorten time-to-market, reduce manual rework, strengthen compliance, and make it far easier to expand into new markets or launch digital sales models without rebuilding their product data foundation from scratch.

Enter OdooPIM: The Operational Backbone for Manufacturing

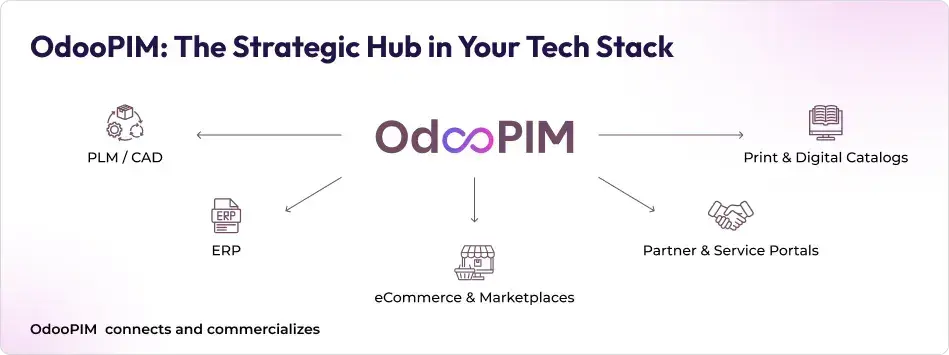

OdooPIM is an integrated PIM software layer engineered for industrial rigor. It operates as the central hub, sitting between your engineering, manufacturing, and commercial operations. This position transforms it from a simple catalog management tool into a system of record that orchestrates the entire product journey.

OdooPIM is built to handle the demanding realities of the manufacturing sector. It provides enterprise PIM capabilities in a streamlined, cloud-based PIM format. This PIM software model delivers the power of the PIM solutions without the traditional complexity and cost.

The platform directly addresses critical manufacturing workflows:

- PIM for product lifecycle tracking provides a single source of truth from prototype to obsolescence.

- Technical attribute management for manufacturers standardizes complex specifications for precision across teams.

- Multi-language product specifications in PIM enable global expansion and compliance.

- PIM for spare parts and components management turns aftermarket service into a streamlined profit center.

- BOM (Bill of Materials) management with PIM synchronizes engineering data with commercial and procurement views.

- CAD data integration with PIM and PIM integration with ERP for manufacturing close the loop between design, production, and sales, eliminating data silos.

What Is Product Information Management (PIM) for Manufacturers?

Product Information Management (PIM) is the system for commercializing engineering and manufacturing data. It translates raw technical specifications, materials, tolerances, certifications, and performance data into compelling, accurate, and channel-ready information for customers, distributors, and global markets.

A PIM system acts as the bridge. It takes the product as defined by engineers and prepares it for the commercial world, ensuring every stakeholder sees consistent, compliant, and customer centric content.

PIM vs. PLM, PDM, and ERP: Defining the Stack

Engineering heavy organizations operate a suite of specialized systems. Understanding where a PIM system fits is key to unlocking its value.

- PLM (Product Lifecycle Management) governs the conception, design, and engineering lifecycle. It’s a process centric system for development stages.

- PDM (Product Data Management) is a subset of PLM, focusing on vaulting and version control for engineering files like CAD drawings.

- ERP (Enterprise Resource Planning) manages the physical and financial life cycle, inventory, procurement, production scheduling, and cost accounting.

These systems excel internally but falter when product information must engage the market. They lack the structure to manage marketing descriptions, multi-language product specifications, digital assets, and channel pricing. They are built for creating and making, not for selling and explaining.

The Essential Role of a Dedicated PIM System

When product data must leave the engineering domain to power sales, partner networks, and digital commerce channels a dedicated PIM software becomes non-negotiable.

A CAD model isn’t a product image; a bill of materials isn’t a catalog description; an internal part number isn’t a SKU. Attempting to force fit PLM or ERP to perform commercial catalog management creates bottlenecks, introduces risk, and slows revenue velocity.

A built PIM system like OdooPIM assumes this commercialization role. It enriches core engineering data, leveraging CAD data integration with PIM and synchronizing BOM (Bill of Materials) management with PIM, with the commercial context needed for revenue generation.

This includes:

- Technical attribute management for manufacturers for filtering and comparison on e-commerce sites.

- Multi-language product specifications in PIM for global compliance and market entry.

- PIM for spare parts and components management, transforming service data into a navigable aftermarket catalog.

- PIM integration with ERP for manufacturing to ensure inventory and order accuracy.

The best PIM solutions for industrial manufacturers among cloud-based PIM platforms, provide this enterprise PIM capability without the overhead of legacy systems. A PIM software like OdooPIM delivers the robust functionality required for complex PIM for product lifecycle tracking.

Core Manufacturing Data Challenges PIM Must Solve

Manufacturers face operational obstacles that fracture efficiency and undermine credibility. These challenges stem from managing product data across disconnected systems, creating friction from engineering to the end customer.

1. Data Silos Create Costly Friction

Information becomes trapped in isolated systems. CAD files live in engineering vaults. Approved vendor lists reside in ERP. Sales specifications are scattered across spreadsheets and local databases. This fragmentation forces teams to manually hunt for data, leading to version confusion and decision-making.

2. Inconsistency Erodes Trust

When business units and regional teams operate independently, conflicting specifications emerge. A component might be listed in millimeters for one market and inches for another. Marketing descriptions fail to match technical datasheets. These inconsistencies create confusion for distributors, cause compliance issues, and damage brand authority. Managing accurate multi-language product specifications in PIM becomes impossible without a unified system.

3. Manual Handoffs Introduce Risk

The transition from engineering release to commercial readiness is a manual process. Engineers email BOMs to marketing. Sales teams rebuild data for their configurators. This process is slow and riddled with transcription errors, leading to mis-specified orders, production rework, and costly returns.

How a PIM System Delivers the Solution

They don’t replace specialized systems like CAD or ERP; instead, they integrate and orchestrate them.

A cloud-based PIM like OdooPIM directly attacks these pain points:

- It eliminates data fragmentation by creating a central hub. CAD data integration with PIM pulls in the latest design files. PIM integration with ERP for manufacturing synchronizes inventory and operational data. This convergence ends the spreadsheet chase.

- It enforces global consistency through governed workflows. Technical attribute management for manufacturers standardizes specifications, units, and naming conventions. Changes are made once and published everywhere, ensuring that a spare part in Frankfurt has the same description as its identical counterpart in the US, a core function of PIM for spare parts and components management.

- It automates commercial handoffs, turning slow, error-prone processes into workflows. BOM (Bill of Materials) management with PIM allows engineering data to be automatically enriched for sales channels.

Learn about PIM vs PRM.

PIM as the Commercial Face of Engineering Data

Product Information Management (PIM) is the bridge between engineering precision and market success. It does not replace the technical systems of product development, but complements PLM and PDM by assuming the role of data commercialization.

From Technical Vault to Commercial Engine

PLM and PDM systems excel at managing the “how” and “why” of a product, its design iterations, engineering approvals, and component relationships. A PIM software is built to answer the “what” and “why buy” for the market. It transforms foundational engineering outputs into compelling commercial assets.

This process begins with intelligent aggregation. Through CAD data integration with PIM, technical drawings and models are ingested not as opaque file references, but as sources for visual assets and dimensional data. BOM (Bill of Materials) management with PIM takes the engineering parts list and enriches it with commercial context, customer facing descriptions, tariff codes, and channel pricing, turning a manufacturing recipe into a sellable product structure.

Speaking the Customer’s Language

The power of an enterprise PIM is realized in its ability to scale and adapt information for diverse audiences. Technical attribute management for manufacturers structures raw specs, torque values, pressure ratings, material grades, into filterable, comparable product features that inform buying decisions.

For global reach, multi-language product specifications in PIM are non-negotiable. This capability ensures that distributors in Berlin, Texas, and Brussels access accurate, localized technical data and marketing content.

Orchestrating the Post-Engineering Lifecycle

OdooPIM extends the commercial narrative across the product journey. It enables comprehensive PIM for product lifecycle tracking beyond the engineering phase, managing information through sales, service, and obsolescence. This includes dedicated PIM for spare parts and components management, transforming internal part numbers into a searchable, marketable after sales catalog.

PIM integration with ERP for manufacturing closes the loop, ensuring commercial data aligns with real time inventory and production status. This integration guarantees that the promises made in the catalog are backed by operational reality.

For industrial manufacturers, the best PIM solutions provide this commercial layer. A cloud-based PIM or PIM software delivers this capability without the infrastructure burden, acting as the customer facing layer over your static engineering data.

Industrial Strength PIM: Turning Pain Points into Control Points

Technical Attribute Management for Manufacturers

For industrial manufacturers, products are defined by non-negotiable specifications. True Product Information Management (PIM) masters this complexity by structuring raw engineering data into a scalable, centric framework.

Mastering Specification Complexity

An advanced PIM manages exact material grades, micron-level tolerances, industry certifications (ISO, UL, CE), regulatory standards, and performance curve data.

This technical attribute management for manufacturers transforms a list of specs into a searchable, filterable product database. Engineers define the parameters; the PIM software organizes them for commercial use, enabling customers and distributors to find products based on exact technical requirements.

Controlling Configurations at Scale

A PIM system handles the complexity of variants through a governed data model. It defines parent-child relationships, manages interdependencies between options, and ensures that only valid configurations are presented in catalog management.

This approach prevents configuration errors, accelerates the quoting process, and ensures that possible product variants have accurate technical data. It is a foundational capability of the best PIM solutions for configurable equipment and engineered-to-order products.

Synchronizing Engineering Changes to the Market

A bill of material revision, a new certification, or a material substitution flows to all customer channels. Manual updates create dangerous lags between the engineering floor and the market.

A robust, cloud-based PIM closes this gap. When a change is approved in PLM or ERP, the integrated PIM system triggers an immediate, controlled update workflow. It ensures that sales sheets, digital catalogs, and multi-language product specifications in PIM reflect the approved state. This direct CAD data integration with PIM and PIM integration with ERP for manufacturing turns engineering change management into a competitive advantage.

This capability is core to the PIM for product lifecycle tracking. It also powers accurate PIM for spare parts and components management, guaranteeing service teams always reference the correct, revision part data.

An enterprise PIM like OdooPIM provides this industrial strength attribute governance. This PIM software model delivers the precision engineering demands with the agility commerce requires.

BOM (Bill of Materials) Management with PIM

The Bill of Materials is engineering’s instruction set for building a product. In a PIM system, it becomes the foundational blueprint for selling and servicing it. Effective BOM management with PIM is the strategic process of converting this operational complexity into commercial clarity.

The PIM as BOM Interpreter

A PIM system does not replicate the multi level BOM structures of PLM or ERP. It acts as their intelligent interpreter. Through PIM integration with ERP for manufacturing and CAD data integration with PIM, the system ingests the authoritative engineering and production data.

The PIM software receives the “as-designed” BOM from PLM and the “as-built” status from ERP, synthesizing a single, accurate commercial truth. It reconciles these views to ensure that what is promised in the catalog matches what can be delivered from the factory floor.

From Manufacturing List to Market Story

An engineering BOM lists internal part numbers, raw materials, and sub assemblies essential for production but irrelevant for sales. A PIM system performs the essential translation.

It enriches these components with commercial metadata: marketing descriptions, SKUs, tariff codes, and product specifications. A “304 Stainless Steel Bracket, 10mm” becomes a “Corrosion-Resistant Mounting Arm.”

Governing Commercial Visibility

Not every component in a BOM is a sellable item. This is where PIM for spare parts and components management demonstrates its strategic value. The PIM system provides control over visibility, determining which assemblies, sub assemblies, and individual parts appear in customer channels.

The final machine is featured in the main catalog, key sub-assemblies are available as service modules, and certified spare parts are listed in the aftermarket portal. This granular control, a hallmark of the PIM solutions for industrial manufacturers, prevents information overload for buyers.

PIM for Spare Parts and Components Management

The aftermarket service business is a revenue stream and a critical customer touchpoint. Success here depends on making the correct part easily findable and orderable. This is why a dedicated PIM system is indispensable.

Aftermarket as a Strategic Engine

After-sales service drives recurring revenue and defines brand loyalty. Inefficient parts identification leads to extended downtime, frustrated customers, and lost service contracts. A specialized PIM software transforms the spare parts catalog from a static PDF into a dynamic, intelligent commercial asset. It directly supports PIM for product lifecycle tracking beyond the initial sale.

Structuring the Service Ecosystem

Effective PIM for spare parts and components management begins with intelligent relationships. A robust PIM system creates definitive links between parent products, serial number ranges, service kits, and individual components. This structure is built upon the foundation of BOM management with PIM, which provides the authoritative parts list for product configuration and revision.

When a service bulletin updates a component, the PIM software immediately reflects the change across linked assemblies and kits. This ensures that service technicians and partners reference the latest, revision information.

Empowering the Service Chain with Enriched Data

A PIM system enriches this internal part number with commercial and technical context. It adds intuitive product descriptions, high resolution imagery, exploded view diagrams from CAD data integration, and clear multi-language product specifications in PIM.

Dealers can filter by machine model, symptom, or failed assembly. Customers can identify parts using visual guides. This capability turns a complex service lookup into a simple, self-guided process, dramatically reducing service calls and error rates.

Multi-Language, Multi-Region Product Communication

Global expansion multiplies product complexity. Beyond translation, manufacturers must adapt technical data to local standards, regulatory codes, and market expectations. A robust PIM system centralizes control, turning global compliance from an administrative burden into a competitive accelerator.

Adapting Specifications, Not Just Translating Words

True multi-language product specifications in PIM go beyond basic text conversion. An advanced PIM software manages the complete regional adaptation of your product data. It governs local units of measure, enforces region compliance labels (CE, UKCA, KC), and adapts technical attribute management for manufacturers to meet local engineering norms.

Centralized Control for Localized Output

The power of an enterprise PIM lies in its “create once, publish everywhere” architecture. You coordinate all localized outputs: translated marketing descriptions, region datasheets, and compliant safety manuals.

You control which product variants, spare parts, or configurations are published to regional catalogs, all managed within the PIM system.

Orchestrating Global Rollouts with Precision

Launching products across borders requires synchronized execution. A cloud-based PIM serves as the command center for these multilingual rollouts. It provides workflows for translation review, regional approval, and scheduled publication. Subsidiaries and distributors receive immediate access to their approved, market-ready product data sets via tailored portals or through direct PIM integration with ERP for manufacturing at the local level.

This capability is fundamental for PIM for product lifecycle tracking on a global scale. A change to a BOM (Bill of Materials) management with PIM due to a regulatory update can be orchestrated and communicated across affected regions, ensuring global consistency and compliance.

This makes a PIM software like OdooPIM one of the best PIM solutions for global growth. It transforms the immense complexity of multi-region communication from an operational risk into a repeatable, scalable process.

CAD and Engineering Data Integration with PIM

The digital thread must connect design to delivery without breaking. CAD data integration with PIM establishes a direct pipeline from the engineering environment to the commercial marketplace.

Defining the Data Flow

The goal is to extract validated design intelligence from CAD and PLM systems and inject it as actionable data into the PIM system.

This strategic flow separates operational from commercial data:

- To PIM: Flows definitive, released product intelligence, final dimensions, approved materials, weight, performance parameters, and 2D/3D visual assets for marketing.

- To ERP: Flows the manufacturable instruction set, the production BOM (Bill of Materials), routings, and detailed component specifications for procurement and scheduling.

From Design Parameter to Product Attribute

A PIM software does more than archive CAD files. It actively interprets them. The system receives a validated set of design data, the “what” of the product, and systematically converts it into commercial language.

A 3D model provides not just a rendering for a website, but dimensional data for spec sheets. A material callout in the design becomes a filterable attribute like “Grade 304 Stainless Steel.”

The Strategic Alignment of Systems

When CAD, PLM, ERP, and PIM operate in tandem, they form a cohesive operational spine.

- A design change approved in PLM flows automatically to the PIM system for commercial update and to ERP for production planning, via PIM integration with ERP for manufacturing.

- The product story told in Texas aligns perfectly with the one in Munich because both originate from the same engineered source. This is essential for accurate multi-language product specifications in PIM and for PIM for spare parts and components management, ensuring global service teams reference the correct revision.

- The handoff from “design complete” to “catalog ready” becomes an automated, reliable process.

An enterprise PIM like OdooPIM, delivered as a cloud-based PIM is engineered for this integration.

PIM Integration with ERP for Manufacturing

- The boundary between a PIM system and an ERP is where operational data meets its commercial purpose. Defining this interface with precision is critical. ERP commands the physical and financial realm, it is the ideal system for inventory, production schedules, cost, and order fulfillment. PIM software governs the commercial narrative, it is the definitive source for product descriptions, marketing content, and technical data.

- This separation of responsibility is the foundation of PIM integration with ERP for manufacturing. ERP remains the system of record for what you have and what it costs. The PIM system is the system of engagement for what you sell and why it matters.

- Integration synchronizes these two domains into a cohesive product story. The ERP pushes core operational facts to the PIM: real-time stock levels, lead times, and logistical status. The PIM supplies the enriched commercial context, compelling descriptions, high-resolution assets, and structured technical attribute management for manufacturers.

- This bi-directional flow is essential for accurate catalog management. A customer sees an in-stock status from the ERP, alongside rich marketing content from the PIM, on a single product page. This ensures service portals display detailed installation guides and real-time availability.

- Integration leverages APIs to create an automated data exchange. You deploy a cloud-based PIM, or an on-premise enterprise PIM, the architecture enables real-time synchronization.

- When a product reaches end-of-life in the ERP, the PIM updates its status across sales channels and triggers workflows for replacement part suggestions. It ensures multi-language product specifications reflect the availability constraints as the operational system.

- OdooPIM exemplifies this integrated approach. As a PIM software, it is designed to plug directly into manufacturing ERPs like Odoo, bridging the gap between the warehouse and the web store.

OdooPIM: The Best PIM for Industrial Manufacturers

OdooPIM is a native, integrated commercial layer for your manufacturing operations. It is an ideal PIM for product lifecycle tracking within the Odoo ecosystem, built to meet industrial complexity.

Native Integration, Not Forced Connection

OdooPIM eliminates the traditional friction of PIM integration with ERP for manufacturing. It operates on the same data model and platform as Odoo ERP, it achieves a level of synchronization that standalone PIM software cannot match. It leverages Odoo’s core manufacturing, inventory, PLM, and sales modules as its foundation.

This native architecture means engineering data flows without custom interfaces. CAD data integration with PIM and BOM (Bill of Materials) management with PIM are inherent functions. A bill of material in Odoo’s manufacturing module is automatically an enriched product record in OdooPIM, ready for commercialization.

Engineered for Industrial Workflows

OdooPIM demonstrates its value by solving key industrial challenges:

- It transforms the engineering BOM into a commercial asset. Sales teams see not just a parts list, but a sellable product with enriched descriptions and imagery, while service teams access the same, for spare parts and components management.

- When a change order is approved in Odoo PIM, it instantly contextualizes the impact. It flags which marketing assets need updates, which sales quotes are affected, and ensures multi-language product specifications in PIM reflect the latest revision, maintaining global accuracy.

- The system automatically feeds accurate, engineering-validated product data, complete with technical attribute management, directly into Odoo’s sales modules, e-commerce, and distributor portals.

As a cloud-based PIM offered through a streamlined PIM software model, OdooPIM delivers enterprise PIM capability without the traditional overhead. For manufacturers already committed to the Odoo ecosystem, it is a strategic choice. It closes the loop between design, production, and revenue, solidifying its position as the best PIM.

How OdooPIM Handles Technical and Commercial Data Together

OdooPIM erases the traditional line between technical precision and commercial appeal. It manages the complete product narrative within a single environment.

A Unified Record for Two Audiences

The PIM system consolidates rigorous engineering data and persuasive marketing content on the product record. Technical attribute management for manufacturers, certifications, performance curves, material specs, exists alongside high resolution images, video, and market descriptions.

The platform’s strength is in its relationships. It builds definitive product families, logically grouping final assemblies, serviceable sub assemblies, and individual spare parts within a single catalog management layer. This hierarchy, informed by native BOM (Bill of Materials) management with PIM, provides a complete commercial map of your product ecosystem.

Precision Governed Data Exposure

OdooPIM provides granular control over information visibility. You dictate which data layer audience accesses:

- See the complete record, full technical specifications, cost data, engineering change history, and real time inventory from PIM integration with ERP for manufacturing.

- Access market ready bundles, approved marketing copy, and region multi-language product specifications in PIM, filtered to their authorized product lines.

- Receive a curated, intuitive view. They interact with attribute selectors that are powered by the backend technical specs, a direct benefit of CAD data integration with PIM feeding accurate dimensional data.

This controlled exposure is a core function of PIM for product lifecycle tracking. It ensures the right information reaches the right user at the right stage of the journey, from configuration to after-sales service.

As an integrated cloud-based PIM, OdooPIM delivers this unified data governance out-of-the-box.

OdooPIM for Product Lifecycle Tracking Beyond Engineering

- A product’s lifecycle extends far beyond its design phase. From launch to discontinuation, stage requires commercial orchestration. OdooPIM provides this command and control for the complete commercial journey.

- OdooPIM manages the product’s status from introduction through phase out. It coordinates availability windows, coordinates promotional campaigns for new releases, and manages end-of-life communications from a central platform.

- OdooPIM eliminates confusion by formally defining product relationships within the catalog management layer. You establish clear successor links, identify approved alternative parts, and communicate upgrade paths. This is vital for PIM for spare parts and components management, ensuring service teams can identify compatible replacements for discontinued items.

- The cost of a poor product transition is measured in stranded inventory, service errors, and customer frustration. OdooPIM prevents this by synchronizing phase-out actions across all customer touchpoints.

- When a product is marked for discontinuation in the integrated ERP, OdooPIM executes a coordinated commercial sequence. It can automatically update multi-language product specifications in PIM to flag “Last Buy” status, push successor product recommendations to sales catalogs, and schedule the archival of obsolete listings from e-commerce sites.

- Powered by PIM integration with ERP for manufacturing, guarantees that channels, direct sales, partner portals, service manuals, tell an accurate story. It turns a complex operational change into a streamlined, professional customer experience.

- This cloud-based PIM delivers enterprise PIM control over the entire commercial lifespan.

Cloud-Based and Enterprise PIM with OdooPIM

- OdooPIM delivers a single, scalable architecture that grows with your operational complexity, from a focused PIM software to a comprehensive enterprise PIM deployment.

- For mid-market and high-growth manufacturers, speed and flexibility are important. OdooPIM operates as a cloud-based PIM, eliminating capital expenditure and IT overhead.

- It provides technical attributes such as catalog management, without the burden of infrastructure management. Teams can deploy quickly, adapt processes in real-time, and scale resources on demand.

- OdooPIM scales to meet enterprise PIM requirements. The platform evolves to manage multi-entity governance, complex approval workflows, and PIM integration with ERP for manufacturing across disparate systems. It centralizes control for global PIM for product lifecycle tracking while empowering regional teams with localized multi-language product specifications in PIM.

- OdooPIMS scalability is foundational for managing intricate product ecosystems. The system handles BOM management with PIM across global supply chains and executes PIM for spare parts and components management for worldwide service networks.

- OdooPIM rejects the false choice between starting small and planning big. The same PIM software can begin as a solution for a single product line or division and expand into the strategic data backbone for the organization.

- Manufacturers can start by solving an acute pain point, streamlining CAD data integration with PIM for a new catalog and gradually extend the platform’s reach. This evolutionary path protects initial investment and avoids disruptive platform migrations. The capabilities that make it one of the best PIM solutions for industrial manufacturers at a departmental level are the same that power global, multi-plant operations.

Strategic Benefits: From Engineering-Centric to Data-Driven Manufacturing

- Moving from engineering-centric operations to a data-driven commercial model is a decisive competitive shift. Product Information Management (PIM) enables this transformation, turning product data into a direct revenue driver.

- A robust PIM system enables faster, accurate quoting by providing sales teams with immediate access to validated configurations and technical attribute management for manufacturers. It powers online catalog management that reflects real-time inventory and engineering truth. By empowering distributors with intuitive self-service portals for parts lookup and ordering, central to effective PIM for spare parts and components management.

- The true strategic value of PIM software lies in its role as the unifying layer. It creates a coherent product data strategy that connects and outlasts individual point solutions. By linking CAD data integration with PIM, PLM, and ERP through PIM integration with ERP for manufacturing, you build a resilient digital thread.

- Manufacturers who implement a built PIM system early secure a durable market advantage. They achieve superior time-to-market by automating the handoff from engineering release to sales-ready information. They offer greater product configurability, because complex BOM management with PIM ensures the option is accurately described.

- Accurate multi-language product specifications in PIM across all channels demonstrate professionalism and reliability.

Implementation Blueprint for OdooPIM in Manufacturing

A successful PIM system deployment in manufacturing requires deliberate, phased execution. This blueprint ensures you build a scalable commercial data foundation without disrupting core operations.

Adopt a Phased, Iterative Rollout

Begin with a focused pilot. Select one complex product line, a high-value business unit, or a sales channel as your initial proving ground. This approach minimizes risk, delivers quick wins to build internal momentum, and allows your team to refine processes before scaling. Success in the first phase provides the blueprint and confidence to expand across additional plants, divisions, and global regions systematically.

Execute Foundational Data Discipline

The integrity of your PIM software depends on the quality of its data foundation. Start with a rigorous audit of existing information across CAD, PLM, ERP, and spreadsheets. Identify gaps, conflicts, and redundant sources.

Design a master taxonomy for technical attribute management for manufacturers. This is not a hierarchy of attributes, values, and units that reflects how engineers and customers buy.

Finally, map the authoritative data flows. Define which fields from CAD data integration with PIM and PLM populate the PIM’s core attributes, and how BOM management with PIM translates into commercial structures.

Establish Clear, Sustained Governance

A PIM system is not a “set and forget” tool. It requires an operational model defining clear ownership and processes.

- PLM/Ownership: Engineering owns the design truth, the source specifications, CAD models, and approved BOMs.

- ERP/Ownership: Operations own the physical and financial truth, inventory, cost, and production status.

- OdooPIM/Ownership: Marketing/Commercial teams own the commercial truth, descriptions, rich media, and channel data.

Governance sustains quality, and mandates workflows for PIM for product lifecycle tracking, including new product introduction and end-of-life transitions. It defines stewardship for multi-language product specifications in PIM and PIM for spare parts and components management. It formalizes the sync rules for PIM integration with ERP for manufacturing to ensure commercial promises match operational reality.

Learn about PIM for the Fashion Industry.

Making OdooPIM the Core of Manufacturing Product Data

- OdooPIM is engineered to be the vital core. It is the definitive convergence point where engineering depth meets commercial clarity. This PIM system translates the precision of your CAD designs and BOMs into compelling market narratives. It synchronizes the rigor of your production floor with the demands of global catalog management. It provides the unified platform for technical attribute management for manufacturers, multi-language product specifications, and PIM for spare parts and components management.

- As a built cloud-based PIM and PIM software solution, OdooPIM delivers enterprise PIM capability with agility. Its native PIM integration with ERP for manufacturing and CAD data integration with PIM close the loop between design, production, and sales.

- Conduct a PIM software comparison through a strict manufacturing lens. Evaluate solutions not on generic features, but on their ability to handle BOM (Bill of Materials) management with PIM, govern complex configurations, and scale across a global service network.

- Benchmark against OdooPIM. Assess its potential to act as the central product data hub for your operations for the next decade. The decision to centralize and master your product data is the decision to lead.

Frequently Asked Questions

1. How is a PIM system different from our existing PLM or ERP?

A PIM system occupies a distinct and critical layer in your technology stack, fundamentally different from PLM or ERP in its core mission. Your PLM (Product Lifecycle Management) is the system for the engineering lifecycle, governing design iterations, prototype testing, and engineering change orders. Your ERP (Enterprise Resource Planning) commands the physical and financial lifecycle, managing inventory, production scheduling, procurement, and cost accounting. In contrast, Product Information Management (PIM) is exclusively architected to manage the commercial lifecycle. Its purpose is not to design or build the product, but to master the data required to sell, service, and support it across channels. While PLM answers “how is it designed?” and ERP answers “how is it built and at what cost?” PIM software answers “what is it, why does it matter, and who should buy it?”

The functional divergence becomes stark when data must leave the engineering and production domain. PLM and ERP contain raw, internal-facing data: engineering BOMs, part numbers, and machine routings. A robust PIM system acts as a sophisticated interpreter and enricher of this data. It performs the essential translation of internal specifications into commercial assets. For example, through CAD data integration with PIM, a 3D model becomes a source for marketing visuals and dimensional specs. BOM (Bill of Materials) management with PIM transforms a manufacturing parts list into a sellable product story. It adds the crucial layer of technical attribute management for manufacturers, organizing raw specs into filterable, comparable features for catalogs and configurators, and manages multi-language product specifications in PIM for global markets.

A PIM system does not replace PLM or ERP; it completes the value chain by becoming the commercial gateway. This is why PIM integration with ERP for manufacturing is vital, it synchronizes commercial promises with real-time inventory and production status. Leading enterprise PIM solutions like odooPIM excel as the PIM for industrial manufacturers by functioning as this central hub. They enable comprehensive PIM for product lifecycle tracking from launch to obsolescence, power dynamic catalog management, and streamline PIM for spare parts and components management. Implementing a cloud-based PIM or PIM software establishes the dedicated layer that ensures your product’s technical excellence is communicated with equal clarity and impact in the marketplace.

2. Why do we need a dedicated PIM for spare parts and components management?

A dedicated PIM for spare parts and components management is essential because your ERP and PLM systems are unequipped for the commercial and service complexities of the aftermarket. ERP treats spare parts as inventory line items, focusing on stock levels, cost, and warehouse location, while PLM lists them as references in a BOM management with PIM structure. This internal, operational view lacks the enriched, contextualized data required for efficient discovery and purchasing by service technicians, distributors, or end-customers. A spare part is not just a stock-keeping unit; it is a critical solution to a breakdown, and finding the correct one quickly helps maintain machine uptime and customer trust.

The operational superiority of a dedicated PIM software lies in its ability to create rich, relational product experiences from raw component data. It links spare parts and kits to machine models, serial number ranges, and assemblies, relationships that are poorly defined in ERP. Through CAD data integration with PIM, it can associate parts with exploded view diagrams and technical schematics for visual identification. It enriches a bare internal part number with descriptions, high resolution images, compatibility notes, and multi-language product specifications in PIM for global service networks. This transformation is critical for effective catalog management in the aftermarket, turning a complex lookup process plagued by phone calls and manuals into a streamlined, self-service portal that reduces service delays and errors.

Robust PIM for spare parts and components management directly supports PIM for product lifecycle tracking beyond the initial sale, managing the service narrative through to obsolescence. It ensures service teams and partners always access the latest, revision accurate information. PIM integration with ERP for manufacturing guarantees that the rich commercial data aligns with real time availability and logistics, so a part shown as compatible is also confirmed to be in stock. Implemented as a cloud-based PIM, it provides the specialized, scalable platform to convert your aftermarket operations from a cost center into a differentiated, profitable service business.

3. Can a PIM handle our complex, configurable products and technical specifications?

A robust PIM system is engineered to manage the complexity of configurable products and detailed technical specifications. Handling this complexity is a differentiator for the PIM solutions targeting industrial sectors. Where generic systems fail, a built PIM software excels by providing a data model that can define product families, variants, options, and interdependencies. This model governs which configurations are valid and ensures that every possible combination has complete, accurate, and market-ready information. It directly leverages BOM management with PIM to maintain the authoritative link between sellable configurations and their underlying manufacturable components.

The core of this capability is technical attribute management for manufacturers. A leading enterprise PIM allows you to define, validate, and control thousands of attributes, from materials and tolerances to certifications and performance curves. These are not static fields but dynamic filters that power advanced search, product comparisons, and guided selling in your catalog management systems. This technical foundation extends to global operations through multi-language product specifications in PIM, Platforms like OdooPIM demonstrate that this high-level functionality is accessible through cloud-based PIM. By utilizing CAD data integration with PIM, these systems can automatically ingest key dimensional and material specifications to populate attribute values, ensuring the commercial data is a true reflection of the engineering design. The synchronization is completed through PIM integration with ERP for manufacturing, which aligns your sellable configurations with production capacity and inventory reality. This end-to-end control over complex product data also enhances PIM for spare parts and components management, as configured machine’s service parts can be accurately determined and presented.

4. How does a PIM system support global expansion with multi-language needs?

A PIM system is the foundational platform for efficient and accurate global expansion, engineered to overcome the chaos of manual, decentralized translation and localization. Unlike managing multiple spreadsheets or regional databases, a centralized PIM software provides a single source of truth for all product information. You can systematically create, manage, and publish multi-language product specifications in PIM, ensuring that technical data, marketing descriptions, and compliance labels are accurately adapted for each target market. This is critical for maintaining brand consistency and eliminating the risk of errors that arise from disparate, unsynchronized translation efforts across different departments or subsidiaries.

An enterprise PIM like OdooPIM manages the complete regional adaptation of your product data. It governs local units of measure, ensures technical attributes comply with local engineering norms, and adapts catalog management output to meet regional regulatory requirements. This capability is vital for PIM for spare parts and components management in a global service network, guaranteeing that a technician in Germany and a distributor in the US are referencing the same part, with instructions and specs in their native language.

A cloud-based PIM or PIM software accelerates time-to-market in new regions by streamlining the localization workflow. It provides processes for translation review, regional legal approval, and publishing to regionalized digital storefronts or distributor portals. CAD data integration with PIM ensures visual assets like schematics are localized, while PIM integration with ERP for manufacturing synchronizes content with region inventory and logistics data.

5. We already have Odoo ERP. What does OdooPIM add?

OdooPIM adds a commercial grade Product Information Management (PIM) layer that is built for the complexities Odoo ERP alone is not designed to handle. OdooPIM operates as the dedicated system of engagement for product information. It provides the advanced data structures, enrichment workflows, and channel publishing intelligence required to transform operational data from the ERP into compelling, accurate, and scalable commercial content.

OdooPIM introduces capabilities for B2B and B2C commerce that go beyond ERP’s scope. It delivers technical attribute management for manufacturers, enabling you to structure thousands of complex specifications for use in filtering, comparisons, and configurators. It masters BOM management with PIM to create sellable product structures and hierarchies from engineering data, and it provides dedicated PIM for spare parts and components management to turn your aftermarket service into a streamlined, self-service revenue channel. It centrally manages multi-language product specifications in PIM and regional catalog management, ensuring consistent, compliant messaging across all markets.

OdooPIM transforms your Odoo deployment from an operational backbone into a complete commercial command center. It enables comprehensive PIM for product lifecycle tracking by adding the governance and storytelling layer for a product’s entire market journey. Its PIM integration with ERP for manufacturing is inherent, guaranteeing that rich commercial data is always synchronized with real time inventory and production status from your ERP.

6. Is a PIM implementation a massive, disruptive project?

A PIM system implementation does not need to be a massive project. With a strategic approach, it can be a controlled evolution that delivers value without operational disruption. The key is rejecting the legacy model of a multi-year rollout. Cloud-based PIM is designed for agility, allowing organizations to start with a focused pilot, such as a single product line, a sales channel, or a need like PIM for spare parts and components management.

The perception of disruption stems from poor planning, not the nature of Product Information Management (PIM) itself. The critical work is foundational and strategic, not technical, conducting a thorough data audit, designing a master taxonomy for technical attribute management for manufacturers, and establishing clear data governance. By defining ownership and workflows upfront, such as how CAD data integration with PIM will flow or how BOM management with PIM translates to commercial structures, you build a blueprint for sustainable scaling. A platform like OdooPIM, with its native ERP integration for manufacturing, significantly reduces technical friction.

When executed with a phased blueprint and supported by a flexible PIM software, the implementation becomes a series of managed enhancements. You can add capabilities, such as rolling out multi-language product specifications in PIM for new regions or extending catalog management to additional divisions. This approach allows the PIM system to grow organically alongside your business, evolving from a departmental tool into a full enterprise PIM backbone.